Laser Sintering Green

LASER SINTERING GREEN

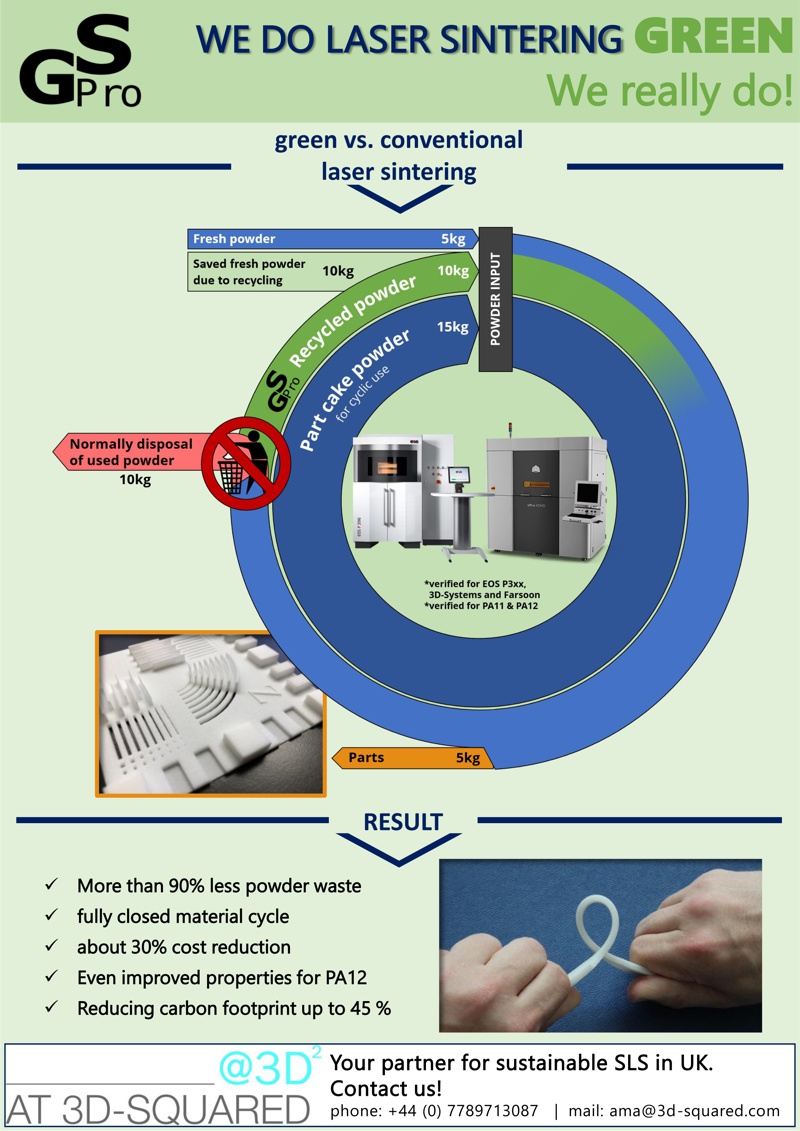

The regular laser sintering process produces a lot of waste powder; powder that has been exposed to heat multiple times grows in particle size and the particles become too large to melt properly which in turn causes surface blemishes and mechanical property variances. Not only is the powder waste an economic annoyance more importantly it is an environmental disaster. The material itself must be refreshed at very high rates between 30% to 50%.

Not refreshing or refreshing with less fresh powder causes often bad looking surface defects which causes itself inappropriate parts. On average SLS builds yield or consume about 6-8% of the powder in your whole part cake. This means you lose about 25-40% of the unfilled PA12 powder because suggested refresh rates are around 50% part cake material. A mid-frame machine has an average throughput of about 0.5kg/h. This means 0.125-0.2kg waste were created per hour. Production machines run about 5,000h/year so in the end you get about 0.6-2t waste per machine per year. In financial terms this translates to throwing away about 30.000-60.000EUR per year! You could buy a new machine or add more capacity every three years if these losses were avoided.

The good news is there are options to re-use that normally wasted powder via GS Pro’s proprietary remanufacturing process. The recycled powders and associated process parameters can even create parts with superior mechanical properties as compared to OEM powders. GS-Pro from Chemnitz, Germany refines the used powder so that it can be used again and again.

There are several ways the refined used powder can be used. It´s possible to use refined powder all alone or to create a closed loop of material use and recycling. Instead of mixing in 50% fresh powder it is possible to reduce the fresh powder amount down to 10-20% by using 35-40% refined powder and then your regular overflow and part cake blend like you are used to. During the past 10 years several customers have established their way to run refined powder on their systems.

3D-SQUARED supports the more sustainable way of laser sintering in UK. If you are interested in using a more sustainable, cost-efficient and waste-free SLS process, contact us so we can address all your questions.